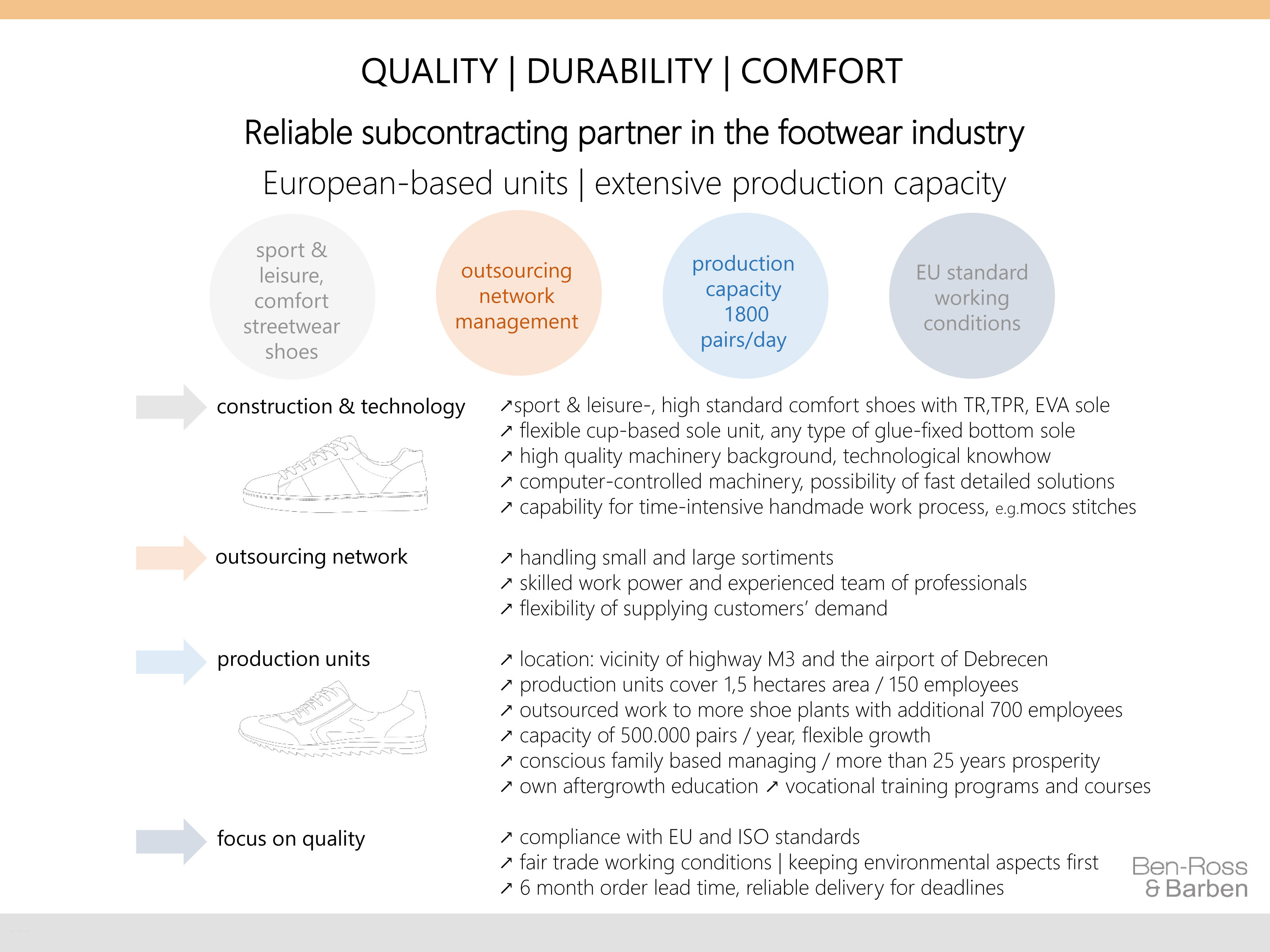

Ben-Ross Shoe Making and Trading Ltd. was founded in March 1993. Business operations at the Tiszakeszi based shoe factory took off to a modest start, having fifteen employees and producing no more than ten to fifteen thousand pairs of shoes per year. However, Ben-Ross immediately started to plan and develop a trendy women´s shoe collection, with the goal of gaining a growing share of the Hungarian market.

By 1997, the company expanded to fifty employees and increased their production to 100 thousand pairs of shoes per year. Ben-Ross products became one of the most demanded Hungarian manufactured shoe brands in the domestic market. At the start of the new millennium, however, much cheaper footwear from the Far East began to stream into Hungary. With their extremely low prices, the local domestic manufacturers did not have a chance at winning the competition. Because of this, the market narrowed for Ben-Ross Ltd., and their orders decreased every year. The management assessed the situation at hand and realized that they had two options: either reduce productivity and the number of employees, or find a new external market to maintain their established quality shoe brand.

In 2002, Ben-Ross Ltd. entered into a partnership with the German based shoe factory, Lugina. The lack of domestic orders was soon compensated for by Lugina, and Ben-Ross manufactured twenty to thirty thousand pairs of shoes for its German partner in their first year of partnership. The company reorganized by launching a sister company, Barben Ltd., maintaining the same profile and ownership as Ben-Ross.

The partnership with Lugina Schuhfabrik proved to be mutually fruitful for both companies. At the beginning of 2004, although domestic market opportunities diminished significantly for Ben-Ross due to the influx of inexpensive goods from the Far East, the two Hungarian shoe factories started to export the German products at full capacity. But, the management is ready to restart the production of its own models whenever Hungarian market conditions turned around.

There was a need for increased output as the Hungarian-German cooperation proved to be more and more successful. Barben Ltd. purchased new plant in Mezocsat, marking the beginning of a dynamic growth for Barben and Ben-Ross.

The factories produced more than 200 thousand pairs of shoes in 2006, and in 2009 exceeded that with 360 thousand pairs made. To further increase capacity, Barben Ltd. invested in an approximately 15,000 square meter piece of land in Tiszakeszi, with roughly 5000 square meter of it containing buildings. With some help from EU funding, the majority of the buildings were entirely renewed by May 2010, reflecting high European standards for their employees.

Barben and Ben-Ross Ltd. were producing 560 thousand pairs of shoes per year and had nearly 300 employees by 2012.

The two factories also outsourced work to 11 more Hungarian shoe plants with an additional 700 employees. Not only did Barben create jobs for the domestic market, they also provided work opportunities for nearly one hundred Hungarians living in Uzhgorod, Mukachevo, and Bereghovo in Transcarpathia, Ukraine between 2003 and 2005. Currently, there are almost 150 ethnic Hungarian employees working for the shoe factory in Oradea, Romania.

Today, Ben-Ross and Barben Ltd. have nearly eleven hundred employees, putting their vast amounts of experience to use while facing the challenges of such a large production. The enterprise is proud to promote development on a local as well as national level with its significant tax contribution each year. The shoe factories in Tiszakeszi and Mezocsat have a goal of producing 600 thousand pairs of shoes a year, in the short run. Moreover, the management and its German partner are also planning to set up a logistics headquarters which will become a supply chain hub for trading shoes all over the world.

The constantly increasing output requires additional skilled workers. Thus, the management has decided to start vocational trainings in its own plants from the end of 2013, securing the new generation of professionals. By now, more than 100 people have already finished the „shoemaker” training courses.

Our social responsibility is to maintain jobs and create new ones in the area. Production processes, sustainability aspects and reprocessing are handled in compliance with environmental protection aspects in accordance with EU standards. The issue of workplace-safety is a top priority for us so we supply fair trade working conditions and circumstances to our employees. Customers are curious about the factory’s working conditions and this also affects the perception of our work. In Hungary we have a very professional work-culture, a high level of work discipline and have strict employment regulations according to the Hungarian Labour Code. The Hungarian Labour Inspectorate – supervision office – monitors compliance with health and safety rules at work which strictly meets European standards. There is a safety representative-employee who works in our units permanently who is responsible for enforcing the rules. The application of new technologies and the modernization of our production processes are the tasks of our employees with appropriate professional qualifications, who provide a workforce ready for challenges.

We succeeded in the development of our industrial machine park for the sake of production efficiency. We work with digitally controlled product preparation processes and we apply new technologies in footwear production. Energy efficiency modernization was succeeded in 2022, GINOP-4.1.4-19- 2020-00909 Széchényi 2020 as a result of the Hungarian state and European Union tender. We successfully applied for technological and infrastructural development by the tenders of the Economic Development and Innovation Operative Program Plus, based on the GINOP Plus-1.2.1-21 call announced by the Ministry of Finance in Hungary in 2021. We are members of the Hungarian Light Industry Association.